torsion test on mild steel rod calculation|mild steel torsion testing machine : private label In this experiment, solid cylindrical specimen of steel or brass will be subjected to a torsional load. The test will be conducted until failure (i. it will end in the fracture). During the test, the angle of . WEBExclusive Content

{plog:ftitle_list}

Play 13,000 free slots online for fun. On this page, we’ll be covering some of the .

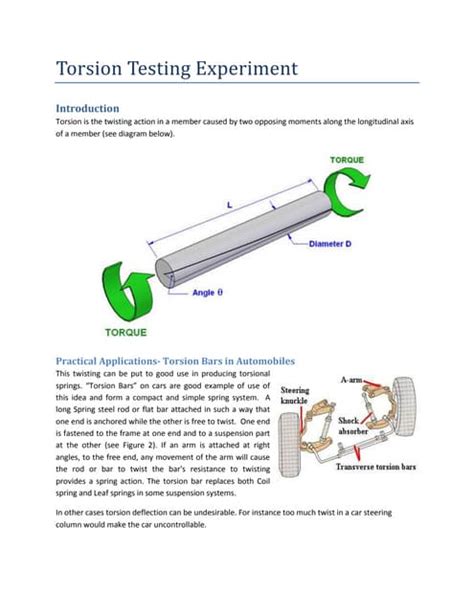

Twisting effect of couple or force is called as torque. It is denoted by double head arrow. Torque applied in a plane perpendicular to the longitudinal axis of a member is called as torsion. See more A torsion test twists the mild steel rod by attaching one end to the machine and applying a moment to the other end, causing the sample to spin around its axis. Both ends of .

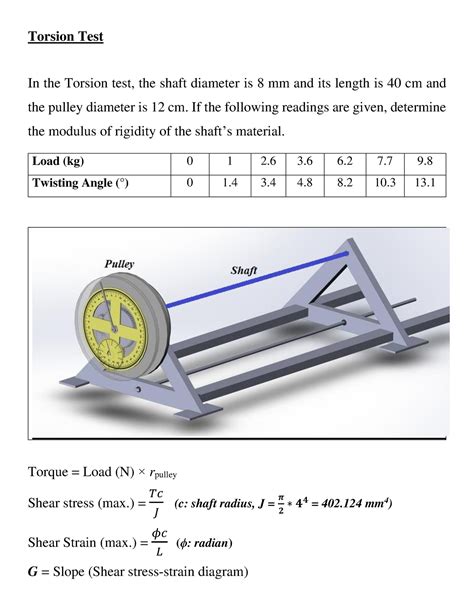

Using the torsion testing machine, we will find out modulus of rigidity and shearing property of mild steel specimen. Main objective of torsion testing experiment is following, To find modulus of rigidity of test machine. To draw .In this experiment, solid cylindrical specimen of steel or brass will be subjected to a torsional load. The test will be conducted until failure (i. it will end in the fracture). During the test, the angle of .Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .

To determine Shear Modulus of Elasticity (G) of some Steel, Aluminum and Brass circular shafts and develop a relationship among the Torque (T0 and Clamping length (L) and the angle of .Torsion Test on Mild Steel. In torsion testing the circular bar is placed in the machine such a way that its longitudinal axis coincides with the axis of the grips and so that it remains straight during the test.

TENSION TEST AIM: Determine tensile Strength of a given specimen using UTM. OBJECT: To conduct a tensile test on a mild steel specimen and determine the following: (i) Limit of .

Torsion Testing of Structural Metals Standards • ASTM E143: Shear Modulus at Room Temperature Purpose • To determine the shear modulus of structural metals Equipment • .Torsion Test on Mild Steel. OBJECTIVE: To study the mechanical properties of mild steel under torsion. STEPS: Click on the Torsion test on Vertical Mild Steel file, a window will open as shown. Click on the NEXT button to move to the . A torsion test twists the mild steel rod by attaching one end to the machine and applying a moment to the other end, causing the sample to spin around its axis. Both ends of the rod can be revolved in opposite directions. . Mathematical calculation. Case 1: Angle of Twist (radians) (θ) = θ * pi / 180 (1) 1*3.14/180: θ = 0.017:

No: 4 Date: AIM To conduct torsion test on mild steel rod and to find its modulus of rigidity. APPARATUS REQUIRED i) Torsion testing machine ii) Mild steel rod THEORY Torsion is quite instrumental in determining the valve of .

EQUIPMENT & MATERIALS 3.1 Equipment Torsion Tester Machine 3.2 Materials Aluminum & Mild Steel ENT 251/4 – Solid Mechanics Laboratory Module 15 Fig. 1 Torsion test machine 3. TORSION TEST The .Torsion of rod test. Data: Mild steel rod: diameter:16mm Length 149.7mm. Aluminum: diameter:16mm Length 149.7mm. 4. CALCULATION a) From the data obtained from the experiment calculate the shear stress of material at the first three angles on the data points of the graph for each material.This torsion test experiment is carried out on rods made of mild steel which is a standard torsion application instrument with in diameter 0 and 0 in length. The rod is connected to a machine that measures torque at one end, and the other end is attached to a chuck that is rotated by a hand-operated carriage.Torsion of Solid and Hollow Shaft Calculator to calculate shear stress, angle of twist and polar moment of inertia parameters of a shaft which is under torsion. The calculator is only valid for sizing of solid/hollow circular shafts. . Typical values Aluminum 6061-T6: 24 GPa, Structural Steel: 79.3 GPa. Notch Sensitivity: A measure of how .

Volume 1. Yusuf Khan, in Encyclopedia of Biomedical Engineering, 2019. Torsion testing. Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and breaking angle of a material or the interface between two materials. Typically a longitudinal sample is placed in a .

1. Tension test on mild steel and tor steel rods 2. Compression test on wooden specimen 3. Double shear test on mild steel and Aluminum rods 4. Torsion test on mild steel rods 5. Impact test on metal specimen 6. Hardness test on metals 7. Deflection test on metal beam 8. Compression test on Helical spring 9. Tension test on Helical spring 10.m) or foot-pound force (ftMethod, Procedure, Observations and Calculations and Related Theories in Torsion Test on Mild Steel & Cast . in torsion for ductile materials generally occur in the plane of maximum shear stress perpendicular to the axis of bar where as for the brittle material failure occurs along 45° hilux to the axis of bar due to tensile stress across .

To conduct torsion test on mild steel. Apparatus:- 1. A torsion test machine along with angle of twist measuring attachment. 2. Standard specimen of mild steel. 3. . Read off co-ordinates of a convenient point from the straight line portion of the torque twist (T- θ) graph and calculate the value of G by using relation.

4 Torsion test 2 5 2Spring test 7 6 Izod Impact test 3 7 Shear test 38 . To conduct a tensile test on a mild steel specimen and determine the following: (i) Limit of proportionality (ii) (ii) Elastic limit . meter rod, test piece & dial gauge. DIAGRAM: THEORY: A Cantilever is a Beam one end of which is clamped and other end is free. A beam .

1.1 Torsion of beams In most steel-framed structures, beams are subject only to bending and not to torsion. In buildings, beams are usually hot rolled I or H sections, proportioned for optimum bending performance about their major axis. These are ‘open’ sections and areexperiment torsion test objective to determine the modulus of rigidity, maximum shearing stress, maximum shearing strain and ratio for the tested specimen. ii . the fracture will occur between 100 to 200 rotations and 200 to 300 rotations for the mild steel and brass material respectively and continued to specimen fracture, the reading of the .Torsion in Shaft Calculator. When a shaft is subjected to a torque or twisting, a shearing stress is produced in the shaft. The shear stress varies from zero in the axis to a maximum at the outside surface of the shaft. SOLID SHAFT SHEAR .

Introduction Tension test on steel rod is the type of test that is used to assess the properties of mild steel, tore steel, and high tensile steel under tension. . The formula for the calculation of gauge length is . 2. The .Tensile Test on Mild Steel In tension test ends of a test piece are fixed into grips connected to a straining device and to a load measuring device. The test involves straining a test piece by tensile force generally to fracture for the purpose of . https://engineers.academy/Analysis of results from a torsion test demonstration on a sample of 0.4% carbon steel. From the torsion test results, we are able .

Torsion Only: Applying only torsional loads to the test specimen. Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen. Failure Testing: Twisting the product, component, or specimen until failure. Failure can be classified as either a physical break or a kink/defect in the specimen.Typical values for K with mild-steel bolts in range 1/4" to 1": normal dry: K = 0.2; nonplated black finish: K = 0.3; . The calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. The calculator is generic an can used for imperial and metric units as long as the use of units are consistent .m) or foot-pound force (ft

torsion test experiment 2 pdf

We determine the dimensions of the rod. Let's assume a length of 2 m (2,000 mm) and a cross-sectional area of 1 cm² (1×10⁻⁴ m²). We observed that the rod elongated by 3 mm. We calculate the strain is the rod according to the formula: ε = ΔL/L₁ = 3/2000 = 0.0015. We calculate the stress, using the stress formula:

A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, .Double shear test is used to determine the shear strength (ultimate shear stress) of the mild steel specimen. Universal testing machine (UTM) is used for performing double shear test. There are two types of UTM namely: screw type and hydraulic type. The latter is easier to operate.IS 1717 (2012): Metallic Materials - Wire - Simple Torsion Test,Third Revision, 2012. F.L. Singer. Strength of Materials, Harper and Row Publishers.

1. Tension test on mild steel rod 2. Compression test on bricks 3. Double shear test on metal 4. Torsion test on mild steel rod 5. Impact test on metal specimen (Izod and Charpy) 6. Hardness test on metals (Rockwell and Brinell Hardness Tests) 7. Deflection test on metal beam 8. Compression test on helical spring 9.

custom skin moisture meter

custom soil moisture & ph meter

Últimas Notícias da MONET. Rob Reiner, responsável por ou.

torsion test on mild steel rod calculation|mild steel torsion testing machine